Meet the Team

Mentors: Dr. Prashant Jindal, Dr. Mamta Juneja

Project interns: Kartik Jangra, Rishi Dhiman, Pranav Gupta, Anirudh Kalra

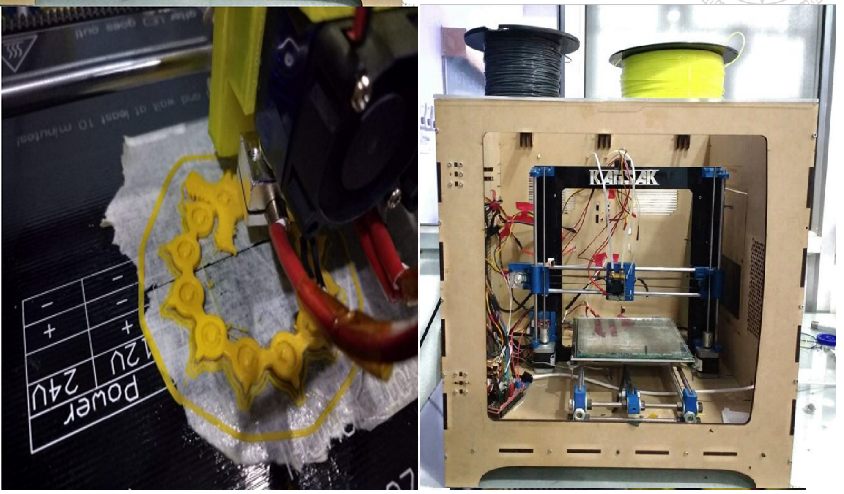

Introduction: Dual Extrusion 3-D Printer.

Problems:

Single extruder 3-D printer uses only one type of material for main body and support body that leads to the wastage of material used.

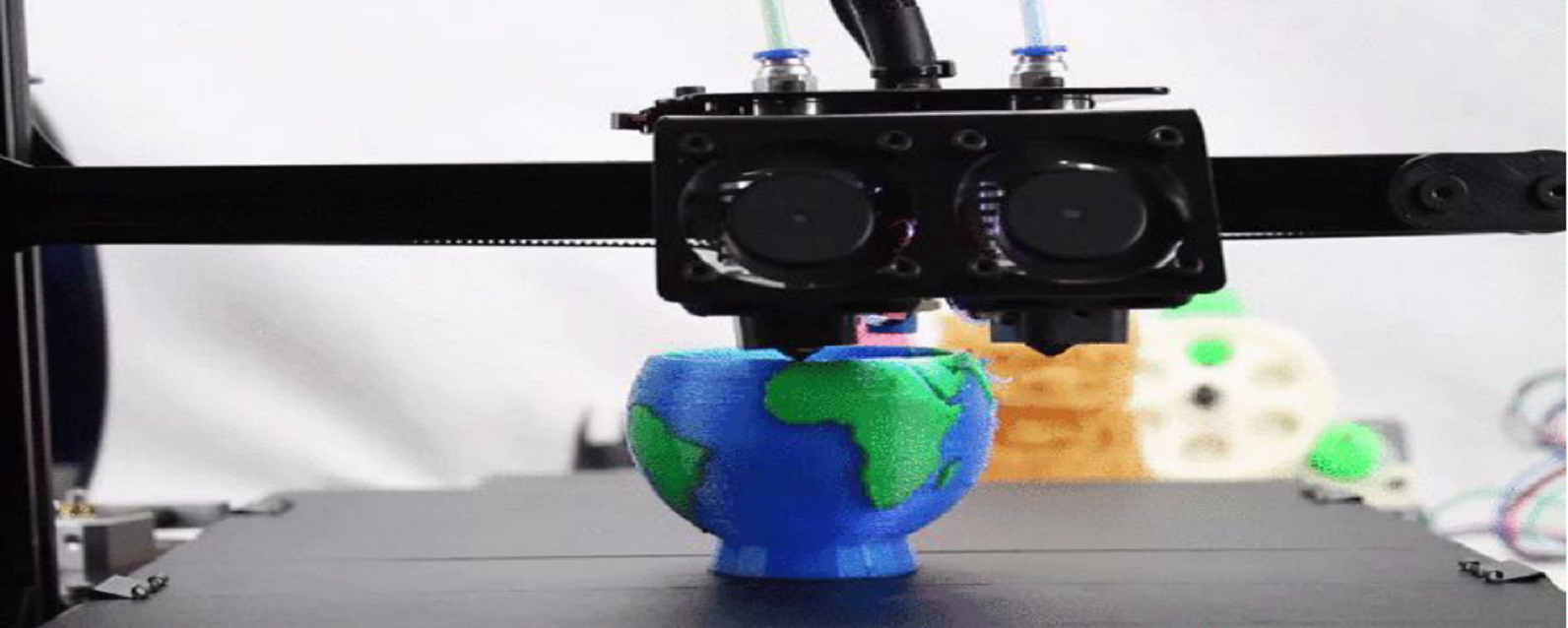

With single extruder we can not have multi colored and multi material prints.

Cheap Dual Extrusion 3-D Printers available in market are not able to print with great precision and accuracy and the good ones are very costly.

With single extruder we can not have multi colored and multi material prints.

Cheap Dual Extrusion 3-D Printers available in market are not able to print with great precision and accuracy and the good ones are very costly.

Achievements

- Successfully printed many parts used in various important projects of DIC lab.

Motive:

An indigenous FDM technology based device to print dual material /colored objects with great precision and accuracy.

Features:

Two inputs and two output system for extrusion i.e. two different filaments (of same or different materials)

Improved heat sink and heat break with better cooling at the hot end assembly.

Soluble support material (like PVA-polyvinyl alcohol) to get a greater surface finish and easy support removal.

Can be converted from bowden tube to direct drive easily.

Technology Stack

- 3-D Printed parts(ABS & PLA)

- Arduino Mega, RAMPS Board

- Stepper Motors

- CAD Software(Fusion 360, Solidworks) for designing printer’s body.

Information

- Name of the Department: UIET, Panjab University

- Name of Project: Design Innovation Centre(DIC)

- Name of Group : : Medical Devices and Restorative Technologies (MDaRT)