MANDATORY DESIGN COURSES

ARTIFICIAL INTELLIGENCE

Level: BE/B.Tech

No. of Credits: 2

Hours: 80-90 hrs.

Period of conducting the course:July 7,2022-August 7,2022

Hours of hands-on Design work: 1-1:30 hrs per day

Mode of Course (Online / Offline Location): Hybrid

Names of Organizing faculty: Dr.Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 36

Under this course,the area covered is development of Computer Aided Diagnosis System (using Deep learning techniques such as neural networks,GANS,hybrid models etc.)for diseases such as Cancer (Brain Tumor,Kidney Tumor,Prostate,Cervix),Glaucoma,Split Canal etc in order to aid the doctors in early detection and thus preventing the disease in its early stages.

This training gave the interns a very precise and clear idea of the CAD system and the steps involved in its creation and were given the opportunity to create their own classification and segmentation system for any of the above mentioned diseases.

Ashwani Rathee,Rishabh Verma, Gautam Chutani , Raag Bhutani, Shashank, Sejal Sharma, Chirag Chanana, Harleen Kaur, Aditya Kumar, Ayush Mishra, Kunal Sharma

Level: BE/B.Tech

No. of Credits: 1

Hours:80-90 hrs

Period of conducting the course: 7th July - 5th August 2022

Hours of hands-on Design work: 2 hours / Day

Mode of Course (Online / Offline Location): Offline

Names of Organizing faculty:Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated: 3

The present innovation relates to an IoT based apparatus and method for measurement of human bite force.

The present disclosure seeks to provide an internet of things (IoT) based apparatus and method for measurement of human bite force. The apparatus consists of a force sensitive resistor sensor for measuring the bite force exerted by the upper teeth and lower teeth of the patient on a bearing plate. The force sensors are employed in the bite force measuring apparatus for measuring the value of compression that has been applied.

The real-time data is recorded and the readings can be conveniently viewed either on an application interface or on the display screen of the apparatus. The application interface gives a convenient way for the analysis of the readings. The apparatus is ergonomically designed and portable. This compact apparatus can measure multiple types of bite forces like unilateral, bilateral and incisal.

In this training the students were taught IOT based human bite force measurement apparatus and method

Kartik Jangra,Raj Rishu, Yuvraj Bind

IoT based Human Bite Force Measurement Apparatus and Methods

IoT based Motion and Grip Sensing Glove

Level: BE/B.Tech

No. of Credits: 1

Hours:80-90 hrs.

Period of conducting the course:7th July - 5th August 2022

Hours of hands-on Design work:2 hours / Day

Mode of Course (Online / Offline Location): Offline

Names of Organizing faculty: Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated. 7

The internship covers designing the integrated circuits with the use of flex sensor along with the esp-32 microcontroller. We have used the esp-32 bluetooth and Wi-fi enabled microcontroller and studied its integration in different circuits.The final product is the glove which is used to assess the finger joint movements of the human hand. Designed to function as a remote device whose movement values are displayed through an app .The device measures all the finger joint angles and grip through accurate sensors, installed on a comfortable fabric glove which the patient just has to wear and clench fingers for routine analysis. The measured data is captured and stored through a mobile application, accessible by both doctor and patient for references and interpretation in real time. Its superior design, digital methodology, comfort of use and real time data management makes it a valuable tool for the patients.

Tanish Raina,Arulsham Bhasin , Tanishq Singh , Ujjwal Raj , MD Nayab Ansari , Naveen Dadwal , Vaishya Ayush Vijay Kumar , Aryan Goyal

In this training the students were taught Pcb designing, Sensor Application , Arduino Basics in detail. They were able to design integrated IoT circuits

Level: BE/B.Tech

No. of Credits: 1

Hours: 18 Hours/week

Period of conducting the course:7th July - 8th August 2022

Hours of hands-on Design work:3 hours / Day

Mode of Course (Online / Offline Location): Hybrid

Names of Organizing faculty:Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated: 41

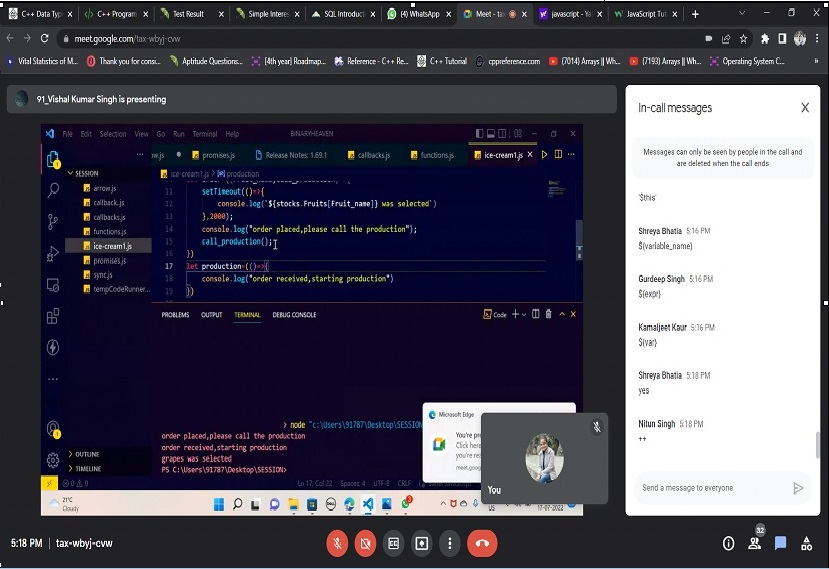

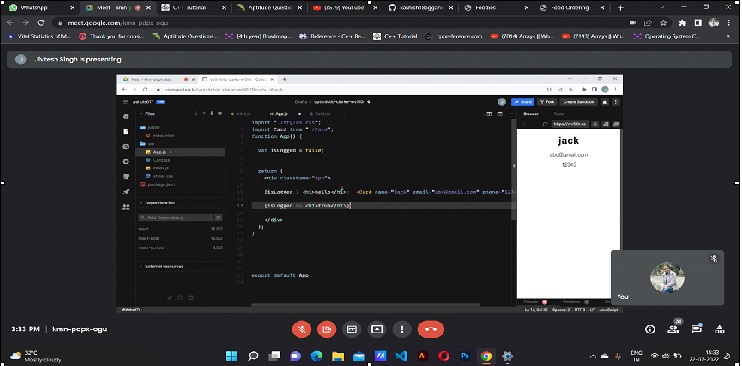

Web Development Summer Training 2022 was based on MERN stack website development. Topics covered under this training include HTML, CSS, JavaScript, React, NodeJS and MongoDB. Assignments based on the previously mentioned topics have been assigned and evaluated. A final website project(dynamic) based on the complete MERN stack has been assigned. Under HTML: all tags and functionalities have been covered; under CSS: styling, animations, selectors, nested lists, flex box, responsive designing, media queries, etc; under JS: async/await, closures, callback, exceptional handling, form validation, cookies, etc; under React: React Bootstrap, React Map, React Table Higher-Order Components, React Code Splitting, React Context, React Hooks, React Flux Concept,React props, React states, React events, React List, React Keys, etc; under NodeJS: Node.js basic, Web application frameworks, Security, How to front end, Databases, Package management Cloud platforms, Source control; under MongoDB: how to Record in a Documents, Database Collections i.e. Grouping Documents, Replica Sets Sharding, Indexes for Improving Query Speed, Aggregation Pipelines Programming Languages.

Vishal Kumar Singh, Riya Gupta, Arham Jain, Kanishk Tyagi, Jivtesh Singh

In this Summer Trainings students were taught to create, implement and deploy a completely functional MERN website of commercial grade.

Web Development (MERN Stack)

Data Science

Level: BE/B.Tech

No. of Credits: 1

Hours: 12 Hours/week

Period of conducting the course:7th July – 8th August 2022

Hours of hands-on Design work: 2 hours / Day

Mode of Course (Online / Offline Location): Hybrid

Names of Organizing faculty:Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated: 43

Medical Statistics of Punjab:Long-term mortality measurement by cause, gender and geographic area has been the requirement of every geographic location. The dashboard on Medical Statistics of Punjab compares the different health related parameters of the region and provides insights on the ratio of death rates, birth rates and infant mortality rates from the past 40 years.

This dashboard helps us compare and study about the indoor and outdoor institutional cases of Punjab and helps in the analysis of the effectiveness of the immunization program of the region. It also provides insights on the top 10 causes of death in Punjab in the above mentioned years. The key skills involved are MS Excel for data cleaning and sorting, and BI tool: Tableau for Data Visualization.

Covid Smart Healthcare System:This dashboard analyses the total number of deaths, cases and recovered because of Covid-19. It also analyse various factors that have led to the spread of pandemic i.e. area density and number of international flights

during the pandemic. Various datasets such as Area Density, Area Population, Number of deaths, cases and recovered, Total number of international flights during the pandemic.

The key skills involved are MS Excel for data cleaning and sorting, and BI tool: Tableau for Data Visualization.

Shahdeep Singh Sandhu(DA LEAD )

Meghna Singh, Sahiba Uppal, Aditi, Yog Gupta and other 15 associates

In this Summer Training students were given different types of industry grade skills in data science and data visualisation using the modern tools.

Level: BE/B.Tech

No. of Credits: 1

Hours:80-90 hrs.

Period of conducting the course:7th July - 5th August 2022

Hours of hands-on Design work:2 hours / Day

Mode of Course (Online / Offline Location): Offline

Names of Organizing faculty:Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated: 3

In this internship we worked on making clear aligners and various substages by using Orthoanalyzer. We learned how to measure teeth movements required to fix collisions, we learned how to make 3D models of scans of various patients and making clear aligners based on those scans. We learned how to use DAQ and connect strain gauges and take measurements on ni max.

Sainyam, Saurabh Vishwakarma, Rishi Sharma, Shristi Richa right at the coast

In this training the students were taught Using Ortho Analyzer software, Making clear aligners, Working with strain gauges, DAQ

Aligner/Bruxism

Embedded System and IoT

Level: BE/B.Tech

No. of Credits: 1

Hours:80-90 hrs.

Period of conducting the course:7th July - 5th August 2022

Hours of hands-on Design work:2 hours / Day

Mode of Course (Online / Offline Location): Offline

Names of Organizing faculty:Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated: 23

Summer training covered the basics of Embedded systems, IoT, and circuit design. This included Interfacing sensors such as temperature sensors, ultrasonic sensors, touch sensors, and passive infrared sensors (PIR) for motion detection. Apart from these actuators such as Stepper motors were also interfaced. Hands-on projects such as a temperature display device and a device with Arduino to show the GPS coordinates of the users' location on it were assigned. In PCB design, trainees were tasked to explore KiCAD libraries, Try out new components/symbols on a schematic board, Try and make connections on the board, Make a proper schematic diagram for any circuit using schema and apply electrical rules check (ERC) to check for problems, associate the respective footprints to the schematic circuit and move footprints in place, and make a schematic diagram for a torch/timer/microcontroller.

The students were taught how to apply automation and IoT Technologies. And after training they were able to apply these technologies to create different IoT enabled smart devices from scratch.

Abhipriya, Sainyam Arya, Saurav Vishwakarma, Rishi Sharma, Shristi Richa

Level: BE/B.Tech

No. of Credits: 1

Hours:80-90 hrs.

Period of conducting the course: 7th July - 5th August 2022

Hours of hands-on Design work: 2 hrs per day

Mode of Course (Online / Offline Location): Offline

Names of Organizing faculty: Dr. Prashant Jindal , Dr. Mamta Juneja

A customized Lithium Nickel Manganese Cobalt Oxide(NMC) based battery pack was designed using a FiniteElement(FE) based model and simulated using a coolant containing 0.001 vol% and 0.005 vol% GrapheneNanoplatelets(GNPs) in a mixture of Ethylene Glycol(EG) and water (50:50) to assess the effectiveness in lowering the operating temperature within the battery pack. The pack’s temperature was set to 60 ◦C. In comparison to pure EG/water fluid,operating temperature range was reduced by about 12% to 24% for 0.001 vol% GNP/EG/water fluid and 24% to 29% for 0.005 vol% GNP/EG/water fluid. From an initial temperature of 60 ◦C, themaximum temperature range for these designs was 42.250 ◦C to 45.760 ◦C. Suggested reasons for this have been, the presence of minor(0.001 vol% and 0.005 vol%) compositions of highly thermally conductive material as GNP, within the regular coolant fluid of EG/water and structural redesigning of the battery pack into two and three tier models.

Abhishek Ranjan, Rishi Dhiman, Anirudh Kalra, Sourav Modgil, Rahul Rao, Ravi kumar, ,Prateek Chaudhary ,Vikas Chaudhary, Manit Kundu,Nishant Gupta

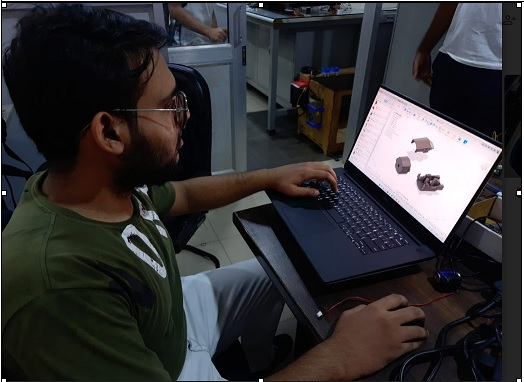

In this training the students went through CAD (Fusion 360) Software, Simulation Software(Ansys Workbench, CFD), 3-D Printing and Microcontrollers like Arduino, Esp-3.

Battery Thermal Management System (BTMS)

3D Modeling

Level: BE/B.Tech

Period of conducting the course: 7th July - 5th August 2022

No. of Credits: 1

Hours:80-90 hrs.

Hours of hands-on Design work: 2 hrs per day

Mode of Course (Online / Offline Location): Offline

Names of Organizing faculty: Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated: 34

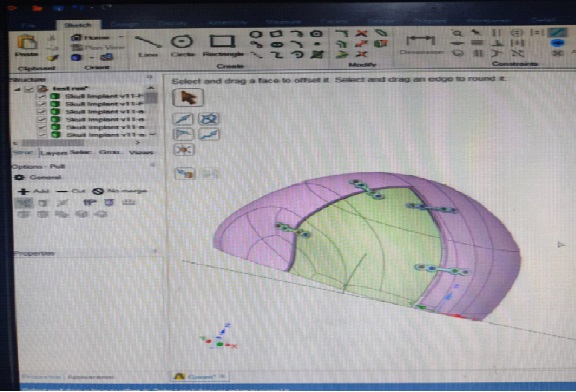

Our aim for this summer internship was to teach the interns how to convert any 2d sketch into a 3d model which further can be assembled , simulated or printed for real use. Interns were acquainted with various techniques including Lofting , Extruding , Joint Operations , Spline and many more to grip Modelling . Demonstration to the basics of simulation were elucidated . Slicing and interpolation were covered using which Cranial Maxillofacial implants are made. Time to time assignments were provided with doubt clearing sessions. Involvement of Team Members as well as the interns were taken care of . Platforms used were Autodesk Fusion 360 , Solidworks , Ansys and Slicer3D.

In this training the students went through CAD (Fusion 360) Software, Simulation Software(Ansys Workbench, CFD), 3-D Printing and Microcontrollers like Arduino, Esp-3.

Naveen Dadwal , Tanish Raina , Ravi Kumar , Dhananjay Moudgil , Vansh Gupta

Level: B.E./B.Tech

Period of conducting the course: 7th July - 4th August 2022

No. of Credits: 1

Hours: 80-90 hrs.

Hours of hands-on Design work: 2 hours / Day

Mode of Course (Online / Offline Location): Offline at DIC Lab

Names of Organizing faculty: Dr. Prashant Jindal , Dr. Mamta Juneja

Number of students participated: 15

In the summer internship covering the domain of 3-D printing, the topics covered were for the deep analysis of the various components and techniques used in 3- D printing. The various assembly methods, error analysis and methods to correct them in case of non-working conditions of printers were also covered. Various types of filaments and printers, including resin printing technology available in DIC, MDART was also briefed. Several online and offline sessions were conducted and hands on experience was given to students where 3-D prints, including the calibration of the printer, were practically examined. Along with that, few advances in 3-D printing like flexible 3-D prints and their filaments were also observed and discussed in equal input from every participant.

The 3D printing process and its assembly were explained to the interns in great detail. They had the option to print their own original artwork. Both the interns and the mentors had a fantastic time.

Harsh Anand Singh, Kartik Jangra, Pranav Gupta, Pragun Gupta, Gunjan Sarode, Rishi Dhiman, Anirudh Kalra

3D Printing

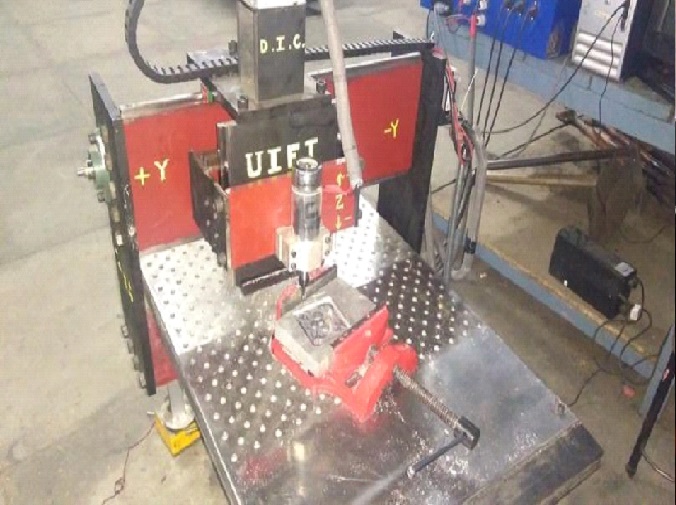

Wire Extruder

Level:B.E/B. Tech

No. of Credits:1

Hours:80-90 hrs

Period of conducting the course:- 7th July 2022- 8th August 2022

Hours of hands-on Design work:2 hours / Day

Mode of Course (Online / Offline Location): Offline/DIC Lab, UIET, Panjab University

Names of Organizing faculty:Dr. Prashant Jindal , Dr. Mamta Juneja

Wire Extrusion machine is the one that transforms low cost plastic beads into a uniform wire that can be used as a filament for 3-D printer.It has the ability to create very complex cross-sections and can also work on brittle materials. 3D printing filament is created using a process of heating, extruding and cooling plastic to transform beads into the finished product in the form of filament. Unlike a 3D printer the filament is pulled rather than pushed through the nozzle to create the filament, the diameter of the filament is defined by the process that takes place after the plastic has been heated rather than the diameter of the extruder nozzle. A different force andspeed is applied to the filament as it is pulled out of the extruder to define the width of the filament, most commonly 1.75 mm or 3 mm diameter. A filament extruder is basically a filament-making machine: on one end, the user pours plastic pellets while on the other end the machine extrudes the filament of desired diameter.

Dhananjay Moudgil, Vansh Gupta, Tanish Raina, Naveen Dadhwal, Harsh Anand Singh, Shivansh Rao, Raj Rishu Keshri.

Workshops/Courses of 2021

Level: BE/B.Tech

Period of conducting the course:July 26,2021-August 23,2021

No. of Credits:2

Hours:80-90 hrs.

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 17(1 st yr)+ 45(2nd year)

Data Analysis is an upcoming field which is in demand and Tableau is a widely used data visualization software all over the world. The first concept to be taught was research as to how and where to look for data followed by sorting the data and cleaning the same. Followed by this, the software- Tableau was taught and doubt sessions were taken on alternate days. With weekly tasks to submit, the students got more efficient at cleaning and sorting the data and data visualization as well. A final Tableau dashboard was prepared by each trainee on the data of COVID-19.

Interns gained various skills such as finding relevant data,cleaning and sorting of data and also publishing of a dashboard using Tableau.

Manvi Nagpal

Data Analysis

Machine Learning

Level: BE/B.Tech

No. of Credits:2

Hours:80-90 hrs.

Period of conducting the course:July 26,2021-August 25,2021

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location):hybrid

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 86( 1st yr)+36(2nd yr).

The internship started with teaching students about the programming language Python. Then they were taught about machine learning and its impact in day to day life. The curriculum for the internship involved maths as well as programming implementation. Supervised Learning, Unsupervised Learning and finally a project was completed. To increase the skills of students, classes were also taken on Image Processing using OpenCV. Quizzes and Tasks were given during the training to keep the students engaged. Certification was given based on performance

Janmejai, Gurnameh, Ashwani , Kunal

This course made the interns well equipped with the knowledge of machine learning and its implementation and the course aimed to improve the performance of all the interns.

Level: BE/B.Tech

Period of conducting the course:July 26,2021-August 23,2021

No. of Credits:2

Hours:80-90 hrs.

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 3(first year)+5(2 nd year)

The DIC MDaRT Website needed a conversion to look modern and match the current era of Website Design and Development, So the project was started with a small number of Web Developers and Designers who then took the initiative to rebuild the pages from scratch and made the website more appealing. Analytic tools were also added to track the number of users who visit the website etc. to give us a better understanding of the role of the website for our lab.

DIC MDaRT Website Reconstruction from scratch was achieved by the interns.

Janmejai, Vishal

Web Development using WordPress

Optimal Designing and Developing Human Prosthetic Limbs

Level: BE/B.Tech

No. of Credits:2

Hours:80-90 hrs.

Period of conducting the course:July 26,2021-August 09,2021

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Hybrid

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant JindalNumber of students participated: 3(first year)+17(2 nd year)

Special

In the one month Summer Training June 2021 provided by MDaRT, DIC; under the project Bionic Prosthetic Arm; training was provided under a number of fields- 3D Modelling and Designing, Embedded Systems and Basic Electronics, PCB and Circuit Designing & Data Acquisition, Processing and Classification.The trainees were first introduced with the subjects on a very basic level and the training was then paced accordingly. No prerequisites were required.• In the 3D modelling and Designing sessions, trainees were made familiar with the softwares- Solidworks and AutoDesk Fusion 360. In these sessions they were taught the basics of 3D Designing, how the interface of these softwares is and how to exactly use the various features and tools provided by them for efficient designing. Various tasks were also assigned.• In the basic electronics and embedded systems, trainees were introduced to the hardware world of the project. It started with the basic introduction of electronics and then moved on to the Microcontrollers- Arduino and Esp32 boards, Actuators- Stepper & Servo followed by Machine Learning and TinyML sessions.• In the PCB and Circuit Designing, trainees were made familiar with the basics of circuit theory and then how to use various softwares like KiCad & AutoDeskEagle to design the printed circuit boards. In Data Acquisition: Biosignals, hands-on experience was provided to the trainees on the OpenBCI and Myoware Muscle Sensor for the acquisition of EEG and EMG data respectively. They were also made familiar with the OpenBCI GUI and the processing techniques.

This course made the interns well aware of Embedded systems and Basic electronics, circuit designing, PCB designing, 3D modelling, App development

Deval Pareek

Level: BE/B.Tech

No. of Credits:2Hours: 80-90 hrs.

Period of conducting the course:July 26,2021-August 9,2021

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 3(1 st year)+16(2nd year

In this Summer training relating to IOMT health-band, members were taught software application development using a blocks based platform - MIT app inventor and Google's cross platform development tool - flutter. Some basics of User Interface (UI) development and prototyping were covered during flutter training and then explored in detail on the platforms Figma and Adobe XD.

Data acquisition was taught through gyroscope, accelerometer and Bio-sensors such as PPG and GSR. An essential aspect of the project is circuit design and simulation. For this first the students were given an introduction to basic electronics and embedded systems which included basics of open-source microcontrollers such as arduino. Then design and simulation were covered using Autodesk Eagle and TinkerCad.

This course enabled all the interns to get knowledge about embedded systems ,PCB designing, App development and helped in their all round development.

Deval Pareek

IoMT Health Band

VR based 3D imaging

Level: BE/B.Tech

Period of conducting the course:July 26,2021-August 9,2021

No. of Credits:2

Hours:80-90 hrs.

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 3(1 st year)+ 12(2 nd year)

In this summer training the students were taught the basics of electronics and circuit knowledge which are important for making circuits , selection of microcontrollers and its coding , circuit simulation , 3d modelling and pcb designing. Then after they were taught about different types of microcontrollers , their specifically and coding structure. They were taught circuit simulation on proteus simultaneously the 3D modelling using solidworks and fusion 360. They were taught circuit Designing and simulation using Autodesk TinkerCad. After teaching them sufficient knowledge of circuits , they were taught PCB designing using Autodesk Eagle. Under App development trainees were taught to work with and develop apps using Flutter

Level: BE/B.Tech

No. of Credits:2

Hours:80-90 hrs.

Period of conducting the course:July 26,2021-August 9,2021

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 3(1 st year)+9(2 nd year)

During the one-month Summer Training of 2021 provided by DIC MDaRT, under the project Single extruder 3D printer

The training was provided under the field of- basic knowledge of 3D printers and 3D printing, 3D Modelling and Designing, Embedded Systems and Basic Electronics, PCB, and Circuit Designing.

The trainees were introduced to the project from a basic level.

• In the 3D modeling and Designing sessions, trainees were made familiar with the software- Solidworks and AutoDesk Fusion 360. In these sessions, they were taught the basics of 3D Designing, how the interface of this software is and how to exactly use the various features and tools provided by them for efficient designing. Various tasks were also assigned.

• In the basic electronics and embedded systems, trainees were introduced to the hardware world of the project. It started with the basic introduction of electronics and then moved on to the Microcontrollers- Arduino and Esp32 boards, Actuators- Stepper & Servo.

• In the PCB and Circuit Designing, trainees were made familiar with the basics of circuit theory and then how to use various software like KiCad & AutoDeskEagle to design the printed circuit boards

This course enabled all the interns to get knowledge about single extruder 3D printer

Shubham Ratra

Single Extruder 3D printer

Dual Extrusion 3D printer

Level: BE/B.Tech

No. of Credits:2

Hours:80-90 hrs.

Period of conducting the course:July 26,2021-August 9,2021

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Hybrid

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 3(1 st year)+12(2nd year)

During the one-month Summer Training of 2021 provided by DIC MDaRT, under the project Dual extruder 3D printer

The training was provided under the field of- basic knowledge of 3D printers and 3D printing, 3D Modelling and Designing, Embedded Systems and Basic Electronics, PCB, and Circuit Designing.

The trainees were introduced to the project from a basic level.

• In the 3D modeling and Designing sessions, trainees were made familiar with the software- Solidworks and AutoDesk Fusion 360. In these sessions, they were taught the basics of 3D Designing, how the interface of this software is and how to exactly use the various features and tools provided by them for efficient designing. Various tasks were also assigned.

• In the basic electronics and embedded systems, trainees were introduced to the hardware world of the project. It started with the basic introduction of electronics and then moved on to the Microcontrollers- Arduino and Esp32 boards, Actuators- Stepper & Servo.

• In the PCB and Circuit Designing, trainees were made familiar with the basics of circuit theory and then how to use various software like KiCad & AutoDeskEagle to design the printed circuit boards.

This course enabled all the interns to get knowledge about Double extruder 3D printer

Shibham Ratra

Level: BE/B.Tech

No. of Credits:2

Hours:80-90 hrs.

Period of conducting the course:July 26,2021-August 9,2021

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 8(1 st Year)+15(2nd year)

Special

During the one-month Summer Training of 2021 provided by DIC MDaRT, under the project Wire extruder 3D printer

The training was provided under the field of- basic knowledge of Wire extruder machine and its application and some basics of knowledge of plastic materials made using the extruder, 3D Modelling and Designing, Embedded Systems and Basic Electronics, PCB, and Circuit Designing.

The trainees were introduced to the project from a basic level.

• In the 3D modeling and Designing sessions, trainees were made familiar with the software- Solidworks and AutoDesk Fusion 360. In these sessions, they were taught the basics of 3D Designing, how the interface of this software is and how to exactly use the various features and tools provided by them for efficient designing. Various tasks were also assigned.

• In the basic electronics and embedded systems, trainees were introduced to the hardware world of the project. It started with the basic introduction of electronics and then moved on to the Microcontrollers- Arduino and Esp32 boards, Actuators- Stepper & Servo, Thermistor, and thermocouple.

• In the PCB and Circuit Designing, trainees were made familiar with the basics of circuit theory and then how to use various software like KiCad & AutoDeskEagle to design the printed circuit boards.

This course enabled all the interns to get knowledge about Wire Extruder

Shubham Ratra

Wire Extruder

IOT Motion Sensing and Grip Sensing Glove

Level: BE/B.Tech

No. of Credits:2

Hours:80-90 hrs.

Period of conducting the course:July 26,2021-August 9,2021

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of Students participated: 4(1st year)+14(2nd year)

In the summer training students were introduced to IoT and knowledge of basic electronics and circuit designing were imparted. They were taught about different types of microcontrollers, their usage and selection criteria. Different types of sensors, their interfacing and coding along with simulations were taught.Students were also told about Real time Data Acquisition. In following weeks 3D modelling using solidworks and fusion 360 were taught and various design tasks were also given. Once the students had learned basic circuit designing and interfacing; pcb designing using Autodesk Eagle was taught and tasks were given. Throughout the training different tasks related to the topics covered were given.

This course enabled all the interns to get knowledge about Iot and other relevant embedded systems information

Chaitanya

Level: BE/B.Tech

Period of conducting the course:July 26,2021-August 9,2021

No. of Credits:2

Hours:80-90 hrs.

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of Students participated: 4(1st Year)+20(2nd year)

In this project internship, the students had been taught the basics electronics and circuit knowledge which are important for making circuits , selection of microcontrollers and its coding , circuit simulation , 3d modelling and pcb designing. then after they were taught about different types of microcontrollers , their specification and coding structure. in WEEK 2 , they were taught circuit simulation on proteus simultaneously the 3D modelling using solidworks and fusion 360. Then in WEEK 3 they were taught circuit Designing and simulation using Autodesk TinkerCad.in week3 after teaching them sufficient knowledge of circuits, they were taught pcb designing using Autodesk Eagle. we had given different tasks to interns related to each session we have covered

This course enabled all the interns to get knowledge about Iot and other relevant embedded systems information

Navudya

Designing and Developing IoT based devices

3D Modelling and Customised Human Dental Aligners

Level: BE/B.Tech

Period of conducting the course:July 26,2021-August 9,2021

No. of Credits:2

Hours:80-90 hrs.

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Hybrid

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Resource Persons: Aayushi Kapoor

Number of Students participated: 6(1st year)+11(2nd year)

Aligners is an alternative method to metal braces and is very convenient to wear. The summer internship 2021 focused on teaching these young minds about the importance of our project, followed by pre-research about it as knowledge about dentistry is required. After pre-research they were taught about the process that we follow. They were taught about the materials and equipment we make use of. Even though they couldn't get hands-on experience (due to the pandemic) we ensured to teach them as much as we could via online meetings. They were asked to make ppts, explore the software along with the help of some previous use cases and finally were asked to make a report on the project

Aayushi Kapoor

This course enabled all the interns to get knowledge about Designing and development of 3D printed Human Dental Aligners

Level: BE/B.Tech

Period of conducting the course:July 26,2021-August 9,2021No. of Credits:2 Hours:80-90 hrs.

Hours of hands-on Design work:1:30 hrs per day

Mode of Course (Online / Offline Location): Online

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of Students participated:7(2nd year)

The internship started with familiarizing the students with the project which is linked to the restorative part in DIC. They were giving a brief introduction about the maxillo and cranio - parts of the skull. Also, they were introduced to how the defects in the skull can hamper their appearance and life. And to restore normalcy, the steps to create a prototype skull using CAD methodology. They were given tutorials on how to extract data from DICOM files and convert them into an STL file. Further, they were taught how to clean and edit the STL as per the requirement of the doctor to reduce the intra-operative time and complexity. Also, they were given a hands on experience on how to create a STL by working on a subject's DICOM

This course enabled all the interns to get knowledge about CAD/CAM Technologies and working medical grade 3D printing

Gerry Dhingra

Restorative Technologies: Maxillo Craniofacial Reconstruction

CAD Kidney Tumour

Level: BE/B.Tech

Period of conducting the course:July 7,2022-August 7,2022

No. of Credits: 2

Hours: 80-90 hrs.

Hours of hands-on Design work: 1-1:30 hrs per day

Mode of Course (Online / Offline Location): Hybrid

Names of Organizing faculty: Dr.Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 14

The internship covered the techniques for data augmentation and made the interns capable of using the tools for denoising , image preprocessing, classification and segmentation using neural networks such UNet,Autoencoders,GANs(Vanilla,pix2pix,CycleGan).

This training gave the interns a very precise and clear idea of the CAD Kidney tumour system and the steps involved in its creation and were given the opportunity to extend the work on already ongoing research

Ashwani, Rishabh, Raag, Gautam Chutani , Shashank, Sejal Sharma, Chirag Chanana, Harleen Kaur, Aditya Kumar, Ayush Mishra

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of conducting the course: 11-07-2022 to 05-08-2022

No. of Credits: 2

Hours: 100 Hours

Hours of hands-on Design work: 100 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

Number of students participated: 25

Different Projects Related to Deep Learning, Machine Learning, Computer vision, Audio processing, Deep Fake Generation and Detection, Drone Detection, Basic of Feature Processing, Web Development, Mobile App development, Cloud Depolyment

BE/B.Tech, ME, M.Tech of Panjab University and Other Institutes.

Naveen Aggarwal

Summer Internship

Elective Design Courses

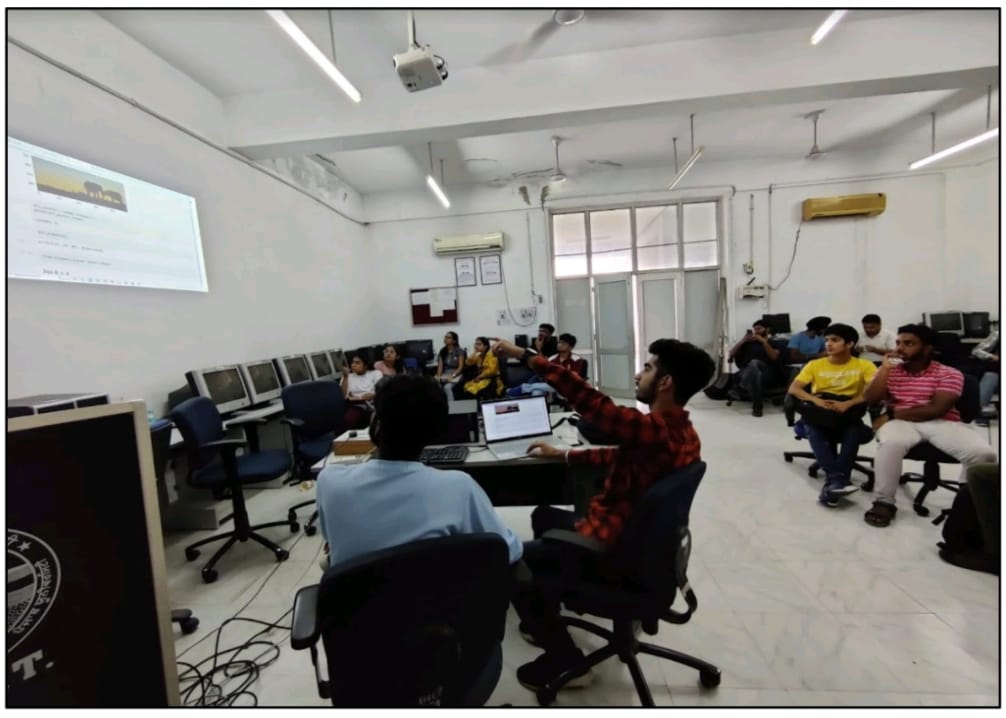

Basic of Embedded System and Arduino

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of conducting the course: 11-07-2022 to 15-07-2022

No. of Credits: 2

Hours: 30 Hours

Hours of hands-on Design work: 15 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

Number of students participated: 25

Basic of Embedded System and Applications of Embedded System, Embedded C Programming,

Introduction to Arduino, and Arduino IDE, Introduction to Electronics (Active/Passive components, Resistance color code, Capacitor, Inductor, Series parallel).Arduino Program Structure, Pin Configuration, Analog/Digital pin interfacing, LED/Switch/Sensors and LCD Interfacing

BE/B.Tech of Panjab University and Other Institutes

Garima Joshi, Krishan Kumar

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of conducting the course: 18-07-2022 to 22-07-2022

No. of Credits: 2

Hours: 30 Hours

Hours of hands-on Design work: 15 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

Number of students participated: 25

Linear Regression + Python Program

Logistic Regression + Python Program, K nearest neighbour + Python Program, SVM Handwriting + Python Program

Feature selection and Extraction + Python Program

BE/B.Tech of Panjab University and Other Institutes

Garima Joshi, Manjeet Kaur

Introduction to Machine Learning

Introduction to Digital Image Processing

Level: BE/B.Tech/ M.Tech/ Research Scholars/Facult

Period of conducting the course: 25-07-2022 to 29-07-2022

No. of Credits: 2

Hours: 30 Hours

Hours of hands-on Design work: 15 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

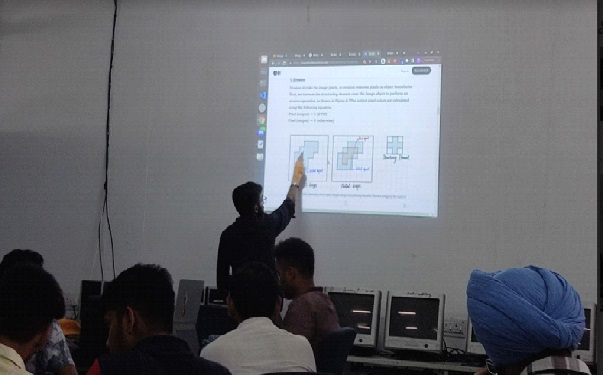

Number of students participated: 25

Introduction to Image/Matrix and Pixel, Components of Image Processing, Basic operations, Image addition/subtraction, Image Enhancement techniques

Edge Detection and Contours Detection using OpenCV

Image Detection and Registration

BE/B.Tech of Panjab University and Other Institutes

Garima Joshi

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of conducting the course: -1-8-2022 to 5-08-2022

No. of Credits: 2

Hours: 30 Hours

Hours of hands-on Design work: 15 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

Number of students participated: 25

Project – Requirements Specifications

Project – Design, Project – Implementation, Project – Testing ,

Prototype Designing, Project Report Documentation

Project – Documentation

BE/B.Tech of Panjab University and Other Institutes

Garima Joshi, Naveen Aggarwal

Project Development

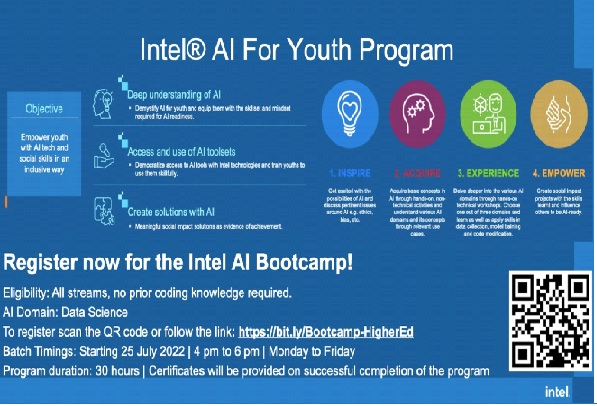

Intel AI for Youth

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of conducting the course: 25-07-2022 to 29-07-2022

No. of Credits: 1

Hours: 20 Hours

Hours of hands-on Design work: 10 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

Number of students participated: 136

Deep Understanding of AI

Gaining AI technical confidence , Demystify AI and problem Solving

learning and applying AI skills independently. Use in Real time Scenario

BE/B.Tech of Panjab University and Other Institutes

Ms. Yukti

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of conducting the course: 01-08-2022 to 05-08-2022

No. of Credits: 1

Hours: 20 Hours

Hours of hands-on Design work: 10 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

Number of students participated: 65

Build necessary technology

Data collection and Presentation, Data pre-processing, Tool Analysis

Application of Data on problem using Tools

BE/B.Tech of Panjab University and Other Institutes

Ms. Yukti

AI Tools Analysis

AI Solution Development

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of conducting the course: 08-08-2022 to 12-08-2022

No. of Credits: 1

Hours: 20 Hours

Hours of hands-on Design work: 10 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen AggarwalNumber of students participated: 65

Demonstrate solutions through AI projects capturing industrial or social impacts, End to End project Design

Implementation using AI Tools, Project – Testing , Project – Documentation

BE/B.Tech of Panjab University and Other Institutes

Ms. Yukti

Level: Research Scholars/Faculty

Period of conducting the course: 15-12-2022 to 12-01-2023

No. of Credits: 2

Hours: 20 Hours

Hours of hands-on Design work: 10 Hours

Mode of Course (Offline): DIC Lab, Block-1, UIET, PU

Names of Organizing faculty: Naveen Aggarwal

Number of students participated: 15

AI, Data Science Tools, Orange Tool Box, Tableau, Advance AI applications, Case Studies on Data Science

Participants will be certified as Intel Enable

Mr. Debashish, Ms. Pooja Yadav

Intel AI for Future Workforce

Workshops / Idea Competitions/ Seminars / Hackathons

StartUp and Incubation Workshop in Medical Devices and Restorative Technologies

Level: BE/B.Tech

Period of workshop: july 8,2019-july 12,2019

No. of Hours:

Hours of hands-on Design work: 2 hrs per day

Mode of Workshop (Online / Offline Location): Offline(DIC Lab ,UIET)

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 45

⦁ Training on basic 3D modeling softwares for medical applications.

⦁ Training on designing and development of basic 3D printing machines

⦁ Exposure to designing and working principles of various medical devices like Motion Sensing Glove, Tooth Shade Detector, Bite Force device, Facial Drill.

All the participants understood :

⦁ Designing and development of 3D models for customized dental aligners, maxillo/craniofacial reconstruction using standard software.

⦁ Designing and Development of single extrusion 3D printer.

⦁ Designing of selected medical devices like Motion Sensing Glove, Tooth Shade Detector, Bite Force Device, Facial Drill

Level: BE/B.Tech

Period of workshop:September 21-23, 2017

No. of Hours:

Hours of hands-on Design work:

Mode of Workshop (Online / Offline Location):

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated:20

Human resources trained on 3D printing can be the future workforce for industry. They can also build a start-up to offer localized services to the society. Five basic skills required for any workforce includes access, manage, integrate, evaluate and create.designing and development of customized Implants using biocompatible materials for various body parts along with their long lasting characteristics

⦁ Designing and development of 3D models for customized dental aligners, maxillo/craniofacial reconstruction using standard software.

⦁ Designing and Development of single extrusion 3D printer.

⦁ Designing of selected medical devices like Motion Sensing Glove, Tooth Shade Detector, Bite Force Device, Facial Drill

Dr. Mamta Juneja,Dr. Prashant Jindal,Dr. Harish Kumar, Dr. Vijay Meena,Dr. Anand Gupta

3D Modeling and Printing Skill Development Workshop

Workshop on Design and Innovation

Level: BE/B.Tech

Period of workshop: June 3,2019

No. of Hours:

Hours of hands-on Design work: 9:30 am -1:00 pm

Mode of Workshop (Online / Offline Location): Offline(Sector 14,PU)

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Prashant Jindal

Number of students participated: 45

All the technologies being worked on were introduced to the participants and the audience.Lecture on Remote sensing was delivered by Dr. MD Behra which was highly insightful and opened a new concept area for all present in the workshop.Interns were also introduced to Social Innovation and Product Designing.

The whole workshop was overall coverage of technology ,new concepts and ideas to be achieved in future and it gave the essence of how important technology is for development of any area.

Dr. MD Behra, Dr. Manish Arora,Prof. Renu Vig

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of workshop: One Day 29 July 2022

No. of Hours: 8

Hours of hands-on Design work: 4

Mode of Workshop (Online / Offline Location): CIL, Panjab University, Chandigarh

Names of Organizing faculty: Dr. Rohit Sharma, Dr. Naveen

Project Preparation, Startup Details, Funding, Business Plan Pitching

BE/B.Tech/ M.Tech/ Research Scholars of Panjab University

Sh. Manveen Singh

Samsung Solve for Tomorrow Event

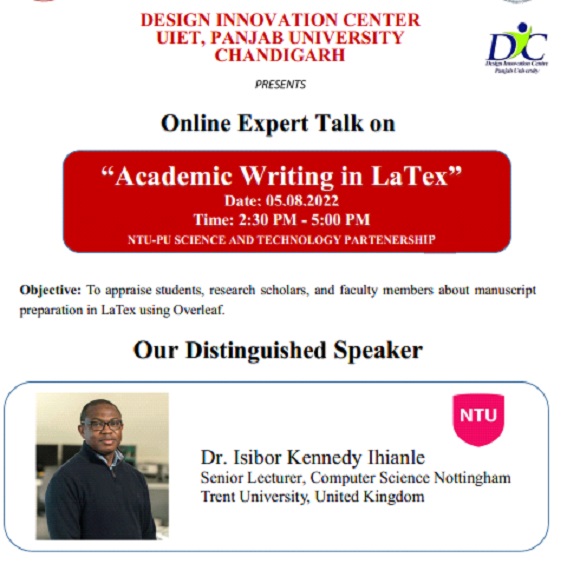

Academic Writing in latex

Level: BE/B.Tech/ M.Tech/ Research Scholars/Faculty

Period of workshop: One Day 05 August 2022

No. of Hours: 3

Hours of hands-on Design work: 1

Mode of Workshop (Online / Offline Location): Online

Names of Organizing faculty: Dr. Naveen Aggarwal, Dr. Naresh Kumar, Dr. Garima

Number of students participated: 60

To apprise students, research scholar about the manscript preparation in LaTex using Overleaf

BE/B.Tech/ M.Tech/ Research Scholars of Panjab University

Dr. Isibor Kennedy lhinale

Level: PG/ Research Scholars/Faculty

Period of conducting the course: 29-09-2022

No. of Credits: 1 Hours: 6 Hours,

Hours of hands-on Design work:4 Hours

Mode of Course (Offline): Chemistry Department, Panjab University, Chandigarh.

Names of Organizing faculty: Naveen Aggarwal

Number of students participated:48

AI for ALL: Empowering Citizens to become AI and Digital Ready

MSc First Year Students

Mr. Manas Mohan

Intel AI for ALL

Startup and Entrepreneurship

Level: BE/B.Tech

Period of workshop: March 13,2018

No. of Hours:2:30 pm-3:30 pm

Mode of Workshop (Online / Offline Location): Offline(Seminar hall,Block 1,UIET)

Names of Organizing faculty: Dr. Mamta Juneja,Dr. Harish Kumar

Number of students participated: 50

⦁ The seminars introduced all the participants with startup and entrepreneurship ideas and their importance in the role of developing the independent economy and was highly insightful.

The seminar was overall coverage of technology ,new concepts and ideas to be achieved in future and it gave the essence of how important startups are for an economy.

Sh. Shrenik Paras Parmar, Founder and CEO

Proodle Solutions Limited (UK)